Your How many screws per 3 x5 hardibacker board images are ready. How many screws per 3 x5 hardibacker board are a topic that is being searched for and liked by netizens now. You can Find and Download the How many screws per 3 x5 hardibacker board files here. Find and Download all free images.

If you’re searching for how many screws per 3 x5 hardibacker board images information connected with to the how many screws per 3 x5 hardibacker board keyword, you have come to the right blog. Our website frequently gives you suggestions for seeking the maximum quality video and picture content, please kindly search and locate more informative video articles and images that match your interests.

How Many Screws Per 3 X5 Hardibacker Board. However some other basic screws dont always seem to finish flush on the surface. If applying 12 Hardibacker cement board over gypsum use minimum 1-34 long corrosion-resistant roofing nails. Fiber cement Board Side B. Make 2-3 passes with a utility or scoring knife.

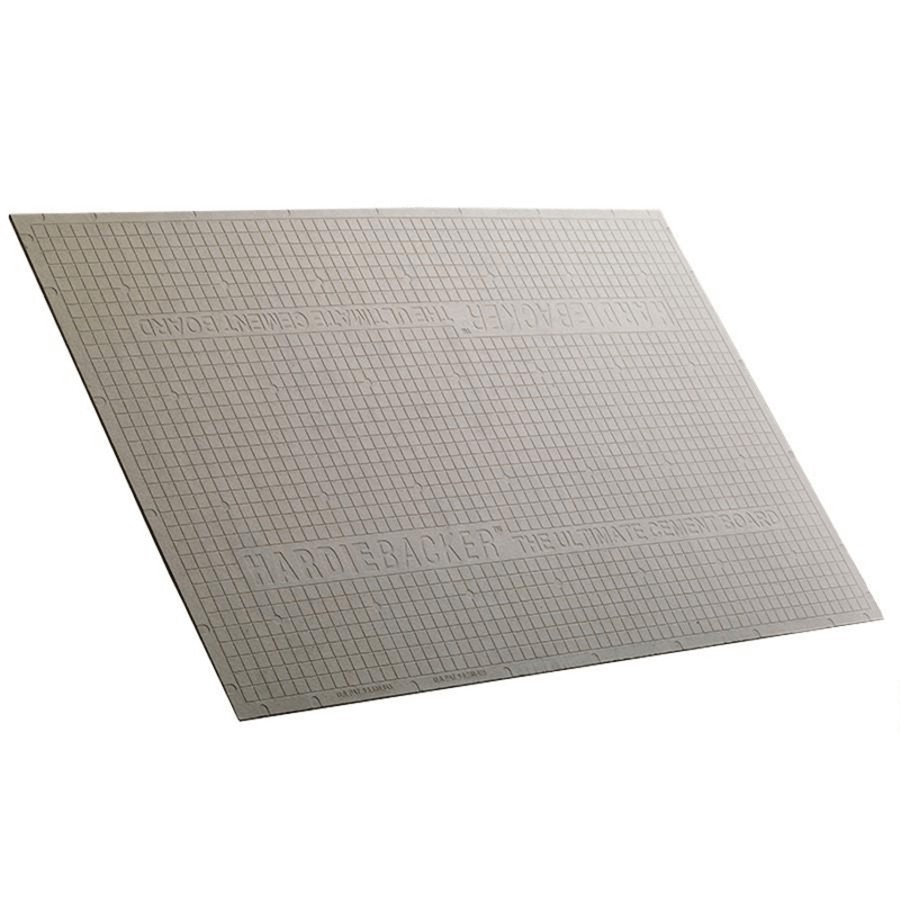

Fasten with screws or nails. A cement board is a combination of cement and reinforcing fibers formed into 3 by 5 feet 91 by 152 cm sheets 14 to 12 inch 64 to 127 mm thick that are typically used as a tile backing board. Ive only seen specific branded screws in 30mm for Hardibacker boards but they seem a bit long for some installations. If compliance with ANSI A10811 is not required minimum 1 long No. 1200 x 800 x 6 mm 12mm. The board of preference for wet areas.

If you arent using these standard sizes use an online deck calculator to determine how many youll need.

If compliance with ANSI A10811 is not required minimum 1 long No. Its based on the manufacturers recommended installation practices. How Many Screws Per 3 X5 Hardibacker Board. Gypsum Wallboard Side A. The basic rule of thumb here is 350 screws for every 100 square feet of deck surface for standard 6 wide boards 55 actual width and 16 spaced joists. The board of preference for wet areas.

Source: lowes.ca

Source: lowes.ca

Screw the backerboard to the sublfloor with 1 14-inch backerboard screws. Can the 12 Hardibacker 500 be used for this weight. 14 Crown Galvanized Underlayment Staples. Holds up to 200 kgm². Make 2-3 passes with a utility or scoring knife.

Source: pinterest.com

Source: pinterest.com

Keep fasteners between 38 in and 34 in from board edges and 2 in from board corners. Can Rock-On and Backer-On screws be used on Hardiplank. TAPE JOINTS PRIOR TO TILING Prior to setting the tiles embed 50mm alkaline resistant Fibatape across joints and feather tile adhesive to leave a. This will amount to roughly 25 screws per 3 x 5 cement board. Keep fi xings between 15mm from board edges and 50mm from board corners.

Source: pinterest.com

Source: pinterest.com

No Rock-On and Backer-On screws are not approved for exterior applications. However some other basic screws dont always seem to finish flush on the surface. Therefore the total weight of a 3x5 board will weigh 225 pounds. Allow a 14-inch gap between the edges of he sheets and all surrounding walls. Make 2-3 passes with a utility or scoring knife.

Holds up to 200 kgm². BENEFITS OF HARDIEBACKER CEMENT BOARD DURABLE. Does not include thin-set to install tile. 3x 5 EZ Grid board with recessed fastener pattern Thickness. Place one hand and knee firmly along the score line then use the opposite hand to pull the board upwards.

Source: homedepot.com

Source: homedepot.com

Highest compressive strength. If applying 12 Hardibacker cement board over gypsum use minimum 1-34 long corrosion-resistant roofing nails. The application is stone on a wall frame. 1200 x 800 x 6 mm 12mm. No Rock-On and Backer-On screws are not approved for exterior applications.

Source:

Source:

8 x 0323 HD self-drilling corrosion-resistant ribbed buglehead screws may be used for floors. 3x 5 EZ Grid board with recessed fastener pattern Thickness. 58 in Type X gypsum wallboard installed. Allow a 14-inch gap between the edges of he sheets and all surrounding walls. A cement board is a combination of cement and reinforcing fibers formed into 3 by 5 feet 91 by 152 cm sheets 14 to 12 inch 64 to 127 mm thick that are typically used as a tile backing board.

Source: lowes.ca

Source: lowes.ca

Allow a 14-inch gap between the edges of he sheets and all surrounding walls. The manufacturer only lists flexural strength and compression strength. 1200 x 800 x 12 mm. Other methods of installation may use more or less material. 14 Crown Galvanized Underlayment Staples.

Source: pinterest.com

Source: pinterest.com

No Rock-On and Backer-On screws are not approved for exterior applications. Allow a 14-inch gap between the edges of he sheets and all surrounding walls. If you arent using these standard sizes use an online deck calculator to determine how many youll need. Holds up to 200 kgm². TAPE JOINTS PRIOR TO TILING Prior to setting the tiles embed 50mm alkaline resistant Fibatape across joints and feather tile adhesive to leave a.

Holds up to 200 kgm². It looks like it may be necessary to pull every bit of that board. Use the fastener pattern as a guide. How Many Screws Per 3 X5 Hardibacker Board. If compliance with ANSI A10811 is not required minimum 1 long No.

Source: pinterest.com

Source: pinterest.com

Can Rock-On and Backer-On screws be used on Hardiplank. 3x 5 EZ Grid board with recessed fastener pattern Thickness. Or screws every 200mm over the entire surface. Keep fi xings between 15mm from board edges and 50mm from board corners. 4 Tape joints prior to tiling.

Source: tools4flooring.com

Source: tools4flooring.com

Keep fasteners between 38 in and 34 in from board edges and 2 in from board corners. Fasten the sheet with cement board screws using a drill-driver making sure the screws are flush with the surface of the sheet or are slightly recessed. Fasten HardieBacker cement board with specified nails or screws as listed in Materials Required every 8 in over the entire surface. 58 in Type X gypsum wallboard installed. HardieBacker board scores a 0 best possible score on the ASTM G21 for mold resistance and a 10 best possible score on the ASTM D3273 test against mold growth.

Source:

Source:

Screw the backerboard to the sublfloor with 1 14-inch backerboard screws. Screw the backerboard approximately every 8 inches or at the locations marked on the sheet by the manufacturer. 9 kg per board 12mm. That is almost 60 screws per sheet. Horizontally or vertically and fastened with minimum 1-14 in Type S drywall screws 8 in oc at board perimeter and in field areas of boards.

Source: pinterest.com

Source: pinterest.com

The application is stone on a wall frame. It sure seems like a lot and is a lot of work Ive laid three sheets so far. BENEFITS OF HARDIEBACKER CEMENT BOARD DURABLE. 1332 042 in Hardibacker 500 backerboard. Does not include thin-set to install tile.

Source: pinterest.com

Source: pinterest.com

8 x 0323 HD self-drilling corrosion-resistant ribbed buglehead screws may be used for floors. The board of preference for wet areas. Holds up to 200 kgm². Use on walls or floors with all types of ceramic or stone tiles thanks to excellent tile adhesion properties. BENEFITS OF HARDIEBACKER CEMENT BOARD DURABLE.

Source: pl.pinterest.com

Source: pl.pinterest.com

Keep fasteners between 38 in and 34 in from board edges and 2 in from board corners. However some other basic screws dont always seem to finish flush on the surface. The stonethinset will weigh 15 pounds per square foot. Cement board adds impact resistance and strength to the wall surface as compared to water resistant gypsum boards. 4 Tape joints prior to tiling.

Source: homedepot.com

Source: homedepot.com

Fasten HardieBacker cement board with specified nails or screws as listed in Materials Required every 8 in over the entire surface. Highest flexibility and up to 3x the compressive strength of competitive boards. Gypsum Wallboard Side A. 4 Tape joints prior to tiling. Fasten the sheet with cement board screws using a drill-driver making sure the screws are flush with the surface of the sheet or are slightly recessed.

A cement board is a combination of cement and reinforcing fibers formed into 3 by 5 feet 91 by 152 cm sheets 14 to 12 inch 64 to 127 mm thick that are typically used as a tile backing board. However some other basic screws dont always seem to finish flush on the surface. Or screws every 200mm over the entire surface. Protects walls floors counters and wet areas from water damage. 9 kg per board 12mm.

Source: pinterest.com

Source: pinterest.com

If compliance with ANSI A10811 is not required minimum 1 long No. Fasten HardieBacker cement board with specified nails or screws as listed in Materials Required every 8 in over the entire surface. Can the 12 Hardibacker 500 be used for this weight. That is almost 60 screws per sheet. The application is stone on a wall frame.

This site is an open community for users to do submittion their favorite wallpapers on the internet, all images or pictures in this website are for personal wallpaper use only, it is stricly prohibited to use this wallpaper for commercial purposes, if you are the author and find this image is shared without your permission, please kindly raise a DMCA report to Us.

If you find this site helpful, please support us by sharing this posts to your preference social media accounts like Facebook, Instagram and so on or you can also save this blog page with the title how many screws per 3 x5 hardibacker board by using Ctrl + D for devices a laptop with a Windows operating system or Command + D for laptops with an Apple operating system. If you use a smartphone, you can also use the drawer menu of the browser you are using. Whether it’s a Windows, Mac, iOS or Android operating system, you will still be able to bookmark this website.