Your How to fix a stripped bolt hole in engine block images are ready. How to fix a stripped bolt hole in engine block are a topic that is being searched for and liked by netizens today. You can Get the How to fix a stripped bolt hole in engine block files here. Get all royalty-free images.

If you’re searching for how to fix a stripped bolt hole in engine block images information connected with to the how to fix a stripped bolt hole in engine block interest, you have come to the right blog. Our site always gives you hints for viewing the highest quality video and image content, please kindly search and locate more enlightening video articles and graphics that fit your interests.

How To Fix A Stripped Bolt Hole In Engine Block. Depending on the application there are multiple levels of Loctite available. In thru-hole applications cover the holes female threads before inserting the bolt. After cleaning and applying a release agent to the bolt put epoxy into the damaged hole and on the bolt. You can get a hand drill with a dual bubble gauge on it to hold 90 degrees then tap.

Model T Ford Forum Soldering Engine Block Cracks From mtfca.com

Model T Ford Forum Soldering Engine Block Cracks From mtfca.com

The complete repair for stripped threads is to use a coil-type thread insert. Step 2 Load your drill with a bi-metal bit that is 116 inch larger than the existing hole. If its cracked its best to get rid o. This worked pretty good. Also - once you get the bolt out you could test and see how much thread is left in the original hole. Another option would be to drill an enormous hole and tap it - like a 12125 but really.

Twist it free by hand and set it aside until you need it later.

Twist it free by hand and set it aside until you need it later. Place them down in the bolt hole and after a few twists of the bolt it should start to become snug. How to fix stripped bolt hole threads on your car DIY with Scotty Kilmer. This worked pretty good. These inserts will give the bolt hole completely new threads which accept the size of the original bolt. Once the epoxy cures install new bolts as needed.

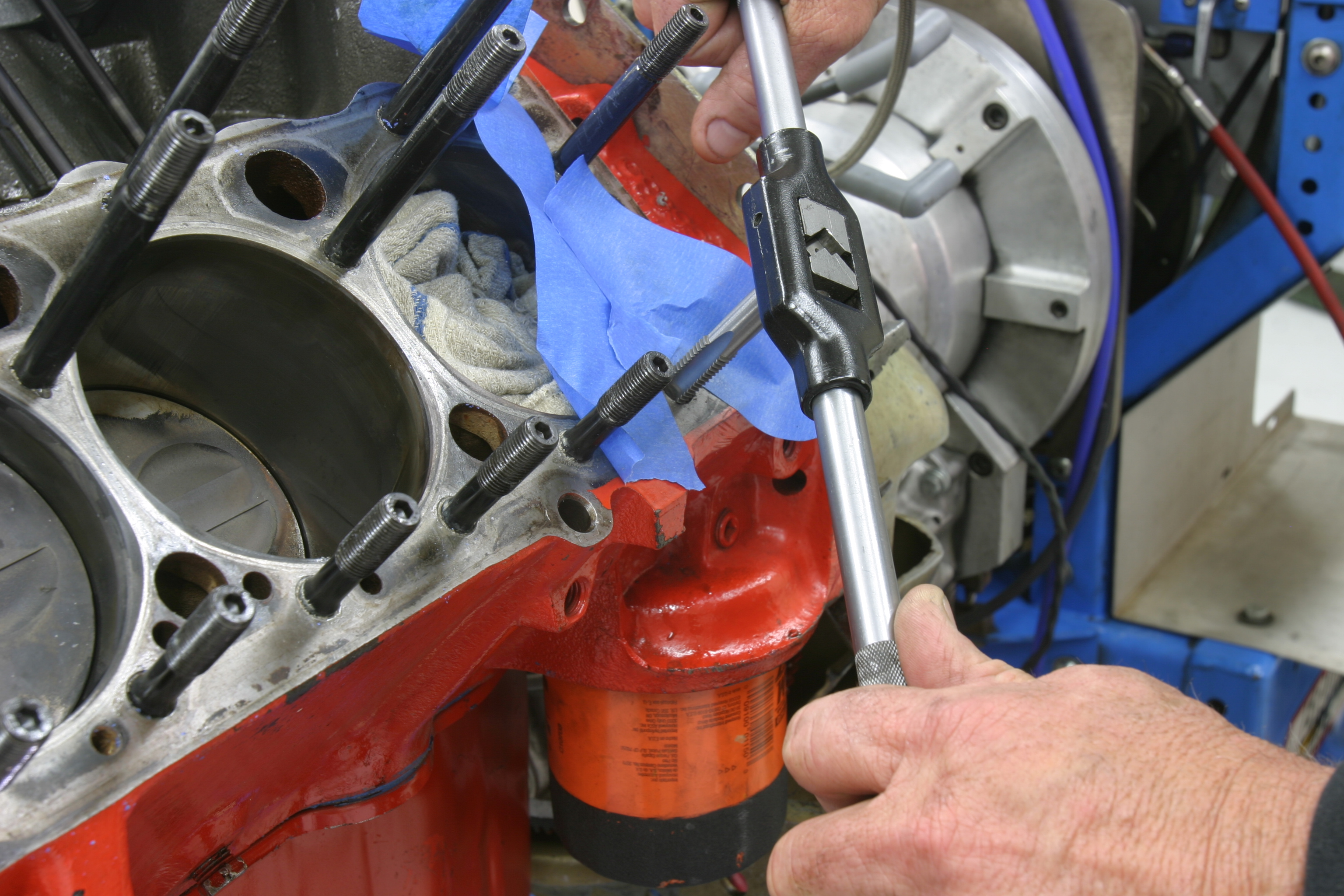

Source: enginebuildermag.com

Source: enginebuildermag.com

I have a video where I purposefully do just that and am able to recover and repair the bolt hole in a small engine. The bolt should turn easily. Stripped bolt hole repair. These inserts will give the bolt hole completely new threads which accept the size of the original bolt. Or make or buy a drill jig that will hold the drill 90.

Source: youtube.com

Source: youtube.com

A thread insert instantly restores the functionality of the previously destroyed bolt hole. There are many different styles of thread repair inserts available but for something as critical as a headbolt there are only three kits I recommend. Remove the original bolt from the stripped bolt hole. Tear a few pieces of aluminum foil off and fold them over. Threading in the bolt will force the epoxy into the existing threads.

Source: enginebuildermag.com

Source: enginebuildermag.com

Excess thread-locker in a blind hole can stop the end of the bolt from bottoming out. Lock N Stitch Full Torque Blind inserts. Excess thread-locker in a blind hole can stop the end of the bolt from bottoming out. Next you could use transfer punches and a cylinder head as a guide to drill three holes. In addition to all the good answers you have been given I would add that if you are speaking of a cast iron block they dont usually get what I would call a hole as a casting they are more prone to cracking.

Source: onallcylinders.com

Source: onallcylinders.com

In thru-hole applications cover the holes female threads before inserting the bolt. This worked pretty good. Threading in the bolt will force the epoxy into the existing threads. Tapping must also be done 90. Place them down in the bolt hole and after a few twists of the bolt it should start to become snug.

Source: mechanic.com.au

Source: mechanic.com.au

If you are careful and good with tools select a proper drill for the new bolt and drill 90. Tear a few pieces of aluminum foil off and fold them over. With the increase in the use of aluminum in engine blocks there has been a significant increase in head bolt threads being pulled or stripped out. These inserts will give the bolt hole completely new threads which accept the size of the original bolt. This worked pretty good.

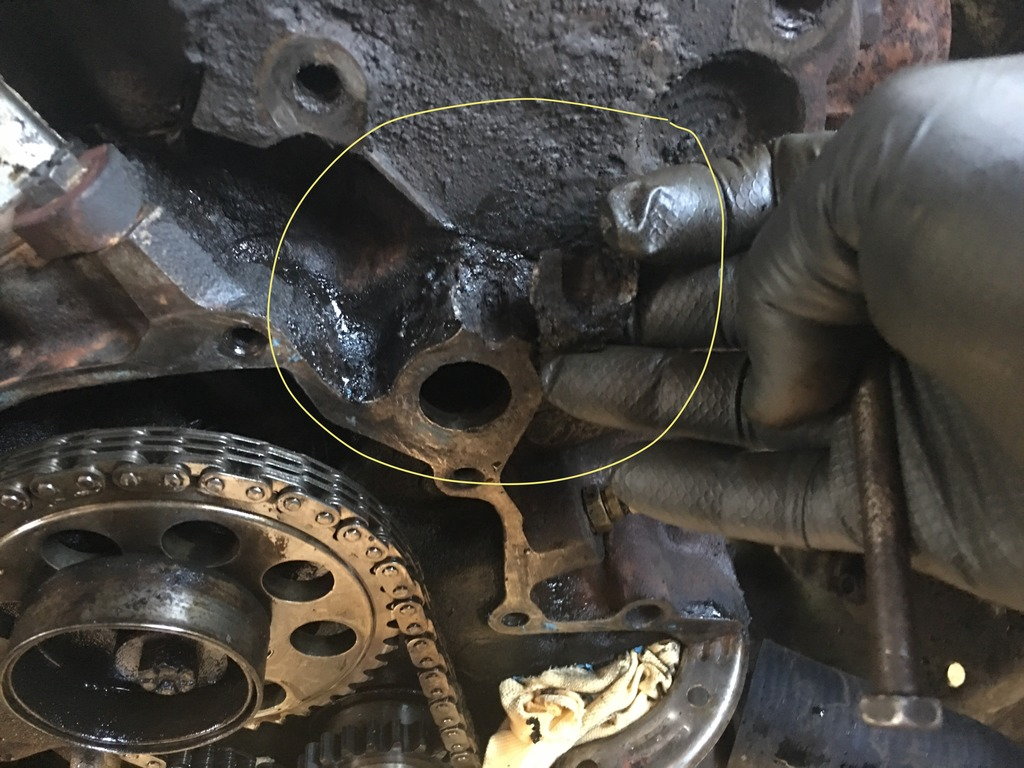

Source: ford-trucks.com

Source: ford-trucks.com

Excess thread-locker in a blind hole can stop the end of the bolt from bottoming out. Once you complete this process you can torque down the bolts like normal. Stripped bolt hole repair. I have a video where I purposefully do just that and am able to recover and repair the bolt hole in a small engine. These inserts will give the bolt hole completely new threads which accept the size of the original bolt.

Source: youtube.com

Source: youtube.com

The first two are used to position head bolt holes that will locate the drill guide on the engine block. The complete repair for stripped threads is to use a coil-type thread insert. How to fix stripped bolt hole threads on your car DIY with Scotty Kilmer. If you are careful and good with tools select a proper drill for the new bolt and drill 90. You can get a hand drill with a dual bubble gauge on it to hold 90 degrees then tap.

Source: howacarworks.com

Source: howacarworks.com

In thru-hole applications cover the holes female threads before inserting the bolt. If its cracked its best to get rid o. Press the bolt into the hole and twist clockwise. I have a video where I purposefully do just that and am able to recover and repair the bolt hole in a small engine. Stripping a bolt hole in an engine block can give you that sinking feelingRe-application of coils can make the threadholes much stronger than before and pr.

Source: mtfca.com

Source: mtfca.com

The complete repair for stripped threads is to use a coil-type thread insert. The holes are not the same depth as the bolts -they are longer - so sometimes part of a fix is using a longer bolt to access those never used threads. I have a video where I purposefully do just that and am able to recover and repair the bolt hole in a small engine. In order to use inserts you must drill the damaged holes slightly larger so that it can take the thread insert. With the increase in the use of aluminum in engine blocks there has been a significant increase in head bolt threads being pulled or stripped out.

With the increase in the use of aluminum in engine blocks there has been a significant increase in head bolt threads being pulled or stripped out. Remove the original bolt from the stripped bolt hole. I go over the multiple options for aluminum thread repairWatch until the end to see some bonus random VWsBrazing Aluminum. Also - once you get the bolt out you could test and see how much thread is left in the original hole. The block must be perfectly flat on the cylinder block face.

Source: rtstools.com

Source: rtstools.com

Threading in the bolt will force the epoxy into the existing threads. If its cracked its best to get rid o. I go over the multiple options for aluminum thread repairWatch until the end to see some bonus random VWsBrazing Aluminum. Excess thread-locker in a blind hole can stop the end of the bolt from bottoming out. These inserts will give the bolt hole completely new threads which accept the size of the original bolt.

Source: ls1tech.com

Source: ls1tech.com

Once you complete this process you can torque down the bolts like normal. I go over the multiple options for aluminum thread repairWatch until the end to see some bonus random VWsBrazing Aluminum. If you are careful and good with tools select a proper drill for the new bolt and drill 90. Old cheap fix maybeJust warshclean it oil out and sharpen the end of bolt a little pack the bolt hole with steel wool as you put the bolt in with out Motor Mont do this a few times with more and more steel wool until the bolt will screw down and hold the right tq if it works then put a little lock tite in when you put it togather for last time what you got to lose. You can get a hand drill with a dual bubble gauge on it to hold 90 degrees then tap.

Source: blog.belzona.com

Source: blog.belzona.com

To perform the thread insert repair process you must use purpose built tools to drill the hole bigger tap new threads and install the metal insert. After cleaning and applying a release agent to the bolt put epoxy into the damaged hole and on the bolt. Excess thread-locker in a blind hole can stop the end of the bolt from bottoming out. There are many different styles of thread repair inserts available but for something as critical as a headbolt there are only three kits I recommend. Depending on the application there are multiple levels of Loctite available.

Source: rtstools.com

Source: rtstools.com

The complete repair for stripped threads is to use a coil-type thread insert. Press the bolt into the hole and twist clockwise. The holes are not the same depth as the bolts -they are longer - so sometimes part of a fix is using a longer bolt to access those never used threads. Depending on the application there are multiple levels of Loctite available. Once you complete this process you can torque down the bolts like normal.

Source: youtube.com

Source: youtube.com

After cleaning and applying a release agent to the bolt put epoxy into the damaged hole and on the bolt. Threading in the bolt will force the epoxy into the existing threads. Pour some Loctite epoxy. Stripping a bolt hole in an engine block can give you that sinking feelingRe-application of coils can make the threadholes much stronger than before and provide much more torquing powerDont worry if you mess up on your money saving project. You can get a hand drill with a dual bubble gauge on it to hold 90 degrees then tap.

Source: dsportmag.com

Source: dsportmag.com

In thru-hole applications cover the holes female threads before inserting the bolt. The holes are not the same depth as the bolts -they are longer - so sometimes part of a fix is using a longer bolt to access those never used threads. These inserts will give the bolt hole completely new threads which accept the size of the original bolt. I have a video where I purposefully do just that and am able to recover and repair the bolt hole in a small engine. Tapping must also be done 90.

Source: dsportmag.com

Source: dsportmag.com

There are many different styles of thread repair inserts available but for something as critical as a headbolt there are only three kits I recommend. The third hole is the most important one. The block must be perfectly flat on the cylinder block face. This worked pretty good. To perform the thread insert repair process you must use purpose built tools to drill the hole bigger tap new threads and install the metal insert.

Source: rtstools.com

Source: rtstools.com

The bolt should turn easily. Remove the original bolt from the stripped bolt hole. Depending on the application there are multiple levels of Loctite available. The first two are used to position head bolt holes that will locate the drill guide on the engine block. To perform the thread insert repair process you must use purpose built tools to drill the hole bigger tap new threads and install the metal insert.

This site is an open community for users to do sharing their favorite wallpapers on the internet, all images or pictures in this website are for personal wallpaper use only, it is stricly prohibited to use this wallpaper for commercial purposes, if you are the author and find this image is shared without your permission, please kindly raise a DMCA report to Us.

If you find this site convienient, please support us by sharing this posts to your preference social media accounts like Facebook, Instagram and so on or you can also bookmark this blog page with the title how to fix a stripped bolt hole in engine block by using Ctrl + D for devices a laptop with a Windows operating system or Command + D for laptops with an Apple operating system. If you use a smartphone, you can also use the drawer menu of the browser you are using. Whether it’s a Windows, Mac, iOS or Android operating system, you will still be able to bookmark this website.